Bahan

| awak | Aluminium(5050 5052 5056) ● | baja | Baja tahan karat | ||||

| Rampung | Dipoles, Dicet | Dilapisi seng | Dipoles | ||||

| Mandrel | alumunium | Baja ● | Baja tahan karat | baja | alumunium | baja | Baja tahan karat |

| Rampung | Dipoles | Dilapisi seng | Dipoles | Dilapisi seng | Dipoles | Dilapisi seng | Dipoles |

| Tipe Kepala | Dome, CSK, Flange Gedhe | ||||||

Spesifikasi

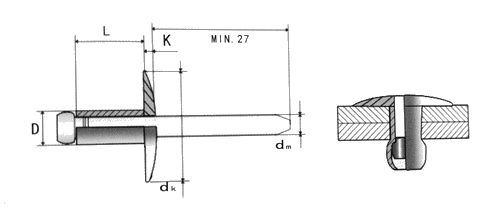

| D1 NOM. | DRILL NO.&UKURAN LUBANG | SENI.KODE | GRIP RANGE | L (MAX) | D NOM. | K MAX | P MIN. | nyukur LBS | TENSILE LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 1/8" 3,2 mm | #30 3.3-3.4 | 1-AS42LF | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | 0,375" 9.5 | 0,065" 1.65 | 1.06" 27 | 120 530N | 150 670N |

| 1-AS43LF | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| 1-AS44LF | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| 1-AS45LF | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| 1-AS46LF | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| 1-AS48LF | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| 1-AS410LF | 0,501-0,625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4,0 mm | #20 4.1-4.2 | 1-AS52LF | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0,468" 12.0 | 0,075" 1.90 | 1.06" 27 | 190 850N | 230 1020N |

| 1-AS53LF | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| 1-AS54LF | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| 1-AS56LF | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| 1-AS58LF | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| 1-AS510LF | 0,501-0,625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| 3/16" 4,8 mm | #11 4.9-5.0 | 1-AS62LF | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0,625" 16.0 | 0,092" 2.33 | 1.06" 27 | 260 1160N | 320 1430N |

| 1-AS63LF | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| 1-AS64LF | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| 1-AS66LF | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| 1-AS68LF | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| 1-AS610LF | 0,501-0,625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| 1-AS612LF | 0,626-0,750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| 1-AS614LF | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| 1-AS616LF | 0,876-1,000 | 22.5-25.4 | 1.200 | 30.5 | |||||||

| 1-AS618LF | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

Aplikasi

Paku keling buta tipe flange gedhe, diameter kepala keling iki tambah akeh dibandhingake karo paku keling buta biasa.Nalika riveting karo konektor, rivet wis area kontak luwih gedhe, lumahing support kuwat, lan bisa nambah kekuatan torsi.Keling pop flange gedhe bisa nahan tegangan radial sing luwih dhuwur.

Industri sing ditrapake: Iku cocok kanggo fastening alus, bahan lumahing pecah lan bolongan pengeboran ekstra gedhe.Keling buta kepala flange gedhe bisa nglindhungi bahan alus.

Apa mandrel rivet wuta kapapar lan ditarik metu nalika nggunakake rivets pop?

Ing proses nggunakake rivet pop, konsumen asring duwe masalah karo inti rivet kapapar lan ditarik metu, kang utamané disebabake nggunakake ora bener.Saiki ayo nuduhake sawetara tips babagan nggunakake paku keling pop.

1. Pilih nozzle keling sing cocog miturut spesifikasi lan model keling pop.

2. Senapan keling kudu digunakake ing tekanan udara sing cocog.Umume dianjurake kanggo nggunakake ing tekanan udara ing ndhuwur 6kg / m2.Yen meksa udhara kurang banget, sirah inti rivet bisa alon deformed lan ditarik metu.

3. Materi bagian rivet kudu konsisten karo awak keling.

4. bolongan Riveting cukup.Bolongan riveting umume 0.1-0.2mm luwih gedhe tinimbang diameter njaba awak keling

5. Cakar telu ing nozzle keling kudu diganti pas wektune sawise dipakai.

Kanthi menehi perhatian marang pituduh ing ndhuwur, masalah paparan inti rivet lan mundur bisa dihindari.