Bahan

| awak | Aluminium ( 5052) ● | baja | Baja tahan karat | |

| Rampung | Dipoles | Dilapisi seng | Dipoles | |

| Mandrel | Baja ● | Baja tahan karat | baja | Baja tahan karat |

| Rampung | Dilapisi seng | Dipoles | Dilapisi seng | Dipoles |

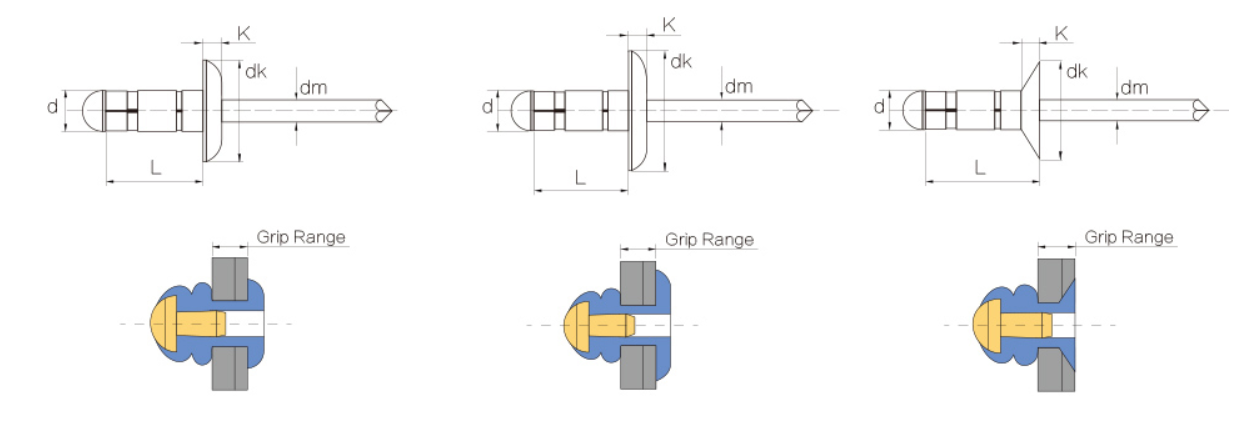

| Tipe Kepala | Dome, CSK, Flange Gedhe | |||

Spesifikasi

| D1 NOM. | DRILL NO.&UKURAN LUBANG | SENI.KODE | GRIP RANGE | L (MAX) | D NOM. | K MAX | P MIN. | nyukur LBS | TENSILE LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 1/8" 3,2 mm | #30 3.3-3.4 | ASMG42 | 0.031-0.134 | 0.8-3.4 | 0.283 | 7.2 | 0,252" 6.4 | 0,051" 1.30 | 1.06" 27 | 135 600N | 202 900N |

| ASMG43 | 0.031-0.187 | 0.8-4.8 | 0.331 | 8.4 | |||||||

| ASMG44 | 0,046-0,250 | 1.2-6.4 | 0.390 | 9.9 | |||||||

| ASMG45 | 0.156-0.312 | 4.0-7.9 | 0.453 | 11.5 | |||||||

| ASMG46 | 0.216-0.375 | 5.5-9.5 | 0.516 | 13.1 | |||||||

| ASMG47 | .250-0.437 | 6.4-11.1 | 0.610 | 15.5 | |||||||

| 5/32" 4,0 mm | #20 4.1-4.2 | ASMG52 | 0.020-0.125 | 0.5-3.2 | 0.283 | 7.2 | 0,312" 7.9 | 0,063" 1.60 | 1.06" 27 | 213 950N | 337 1500N |

| ASMG54 | 0,046-0,250 | 1.2-6.4 | 0.390 | 9.9 | |||||||

| ASMG55 | 0.125-0.312 | 3.2-7.9 | 0.453 | 11.5 | |||||||

| ASMG56 | 0.156-0.375 | 4.0-9.5 | 0.516 | 13.1 | |||||||

| ASMG57 | 0.250-0.437 | 6.4-11.1 | 0.610 | 15.5 | |||||||

| ASMG58 | 0,250-0,500 | 6.4-12.7 | 0.681 | 17.3 | |||||||

| 3/16" 4,8 mm | #11 4.9-5.0 | ASMG64 | 0,062-0,250 | 1.6-6.4 | 0.421 | 10.7 | 0,386" 9.8 | 0,071" 1.80 | 1.06" 27 | 296 1320N | 450 2000N |

| ASMG65 | 0.079-0.315 | 2.0-8.0 | 0.492 | 12.5 | |||||||

| ASMG66 | 0.125-0.375 | 3.2-9.5 | 0.587 | 14.9 | |||||||

| ASMG67 | 0.187-0.437 | 4.8-11.1 | 0.610 | 15.5 | |||||||

| ASMG68 | 0,250-0,500 | 6.4-12.7 | 0.681 | 17.3 | |||||||

| ASMG610 | 0.345-0.590 | 9.0-15.0 | 0.783 | 19.9 | |||||||

| ASMG612 | 0,500-0,781 | 12.7-19.8 | 0.992 | 25.2 | |||||||

Aplikasi

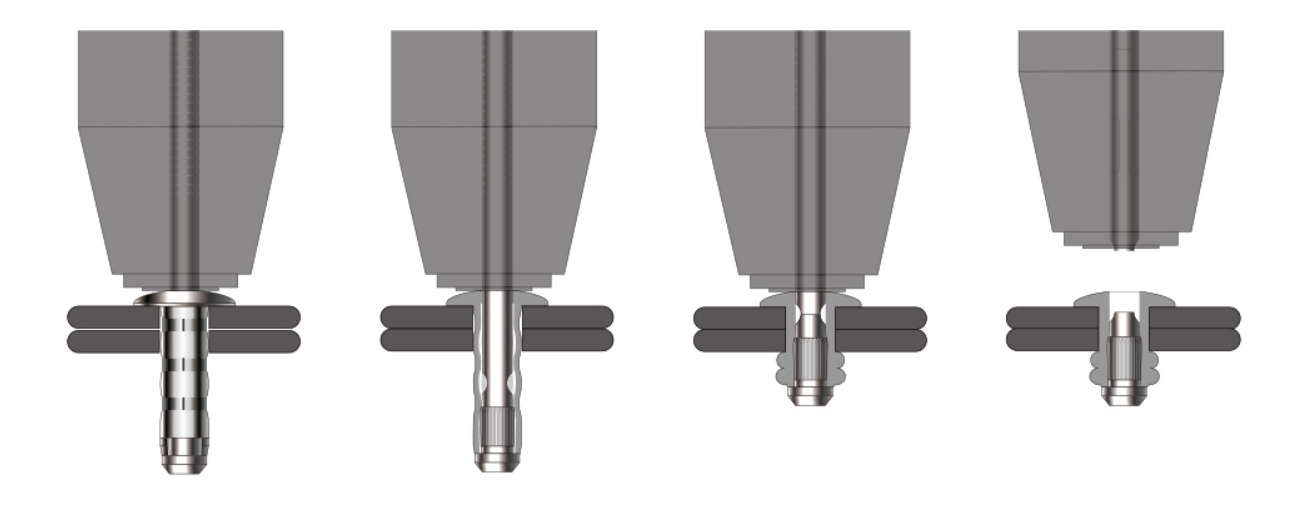

Paku keling multi-Grip nduweni jangkauan genggeman sing amba.Sajrone riveting, inti rivet narik mburi awak rivet menyang wangun drum pindho, clamps loro anggota struktural kanggo riveted tightly, apik sealing kanggo resistance cuaca lan nyuda meksa ing lumahing anggota struktural.Paku keling pop multi-grip kasedhiya ing bahan aluminium, baja lan stainless steel, lan duwe pilihan kepala kubah, kepala csk lan kepala flange gedhe.

Aplikasi: Multi-grip rivets wuta utamané digunakake kanggo riveting macem-macem bagean struktur lancip ing macem-macem kendaraan, kapal, construction, mesin, electronics, wadhah, kasus aluminium, kasus peralatan lan industri liyane.

Rivet pop minangka bagean riveting, sing cocok kanggo riveting saka akeh bahan.Wis pasukan fastening kuwat.Ing wektu sing padha, materi sing digunakake apik banget, lan tingkat proses manufaktur relatif dhuwur.Kinerja keling pop sing diprodhuksi ditingkatake

Perawatan permukaan umum paku keling pop kalebu:

1. Proses Electroplating: proses perawatan lumahing umum bisa digunakake ing akeh bagean logam.Proses elektroplating digunakake ing paku keling pop, sing bisa nglindhungi rivet pop lan nyegah saka nyandhang utawa karat.

2. Paint proses baking: nambah kaendahan pop rivets, lan proses werna beda miturut kabutuhan.Werna padhang lan ora gampang luntur, sing uga bisa nglindhungi permukaan paku keling pop nganti sawetara.

Kanthi perkembangan industri modern, paku keling pop ora mung luwih sampurna ing kinerja, nanging uga katon apik banget, kanthi efek hiasan sing apik, lan ningkatake ekspansi bertahap saka ruang lingkup aplikasi rivet pop.