Bahan

| awak | Aluminium (5052) | baja | Baja tahan karat ● | |

| Rampung | Dipoles | Dilapisi seng | Dipoles | |

| Mandrel | baja | Baja tahan karat | baja | Baja tahan karat ● |

| Rampung | Dilapisi seng | Dipoles | Dilapisi seng | Dipoles |

| Tipe Kepala | Dome, CSK, Flange Gedhe | |||

Spesifikasi

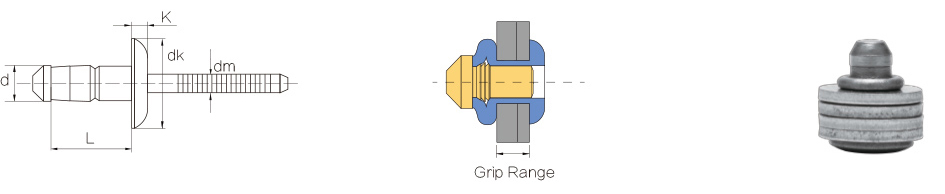

| Ukuran | ngebor | Bagian No. | M | Range grip | B | K | E | nyukur | Tarik |

| maks | maks | maks | maks | KN | KN | ||||

| 3.2 (1/8") |  | BBP61-0408 | 8.9 | 1.0-3.0 | 6.6 | 1.1 | 2.1 | 1.6 | 2.0 |

| BBP61-0411 | 11.4 | 3.0-5.0 | 6.6 | 1.1 | 2.1 | 1.7 | 2.0 | ||

| BBP61-0414 | 13.6 | 5.0-7.0 | 6.6 | 1.1 | 2.1 | 3.2 | 2.0 | ||

| 4.0 (5/32") |  | BBP61-0509 | 10.1 | 1.0-3.0 | 8.0 | 1.5 | 2.6 | 5.2 | 4.0 |

| SSP01-0512 | 12.5 | 3.0-5.0 | 8.0 | 1.5 | 2.6 | 5.2 | 4.0 | ||

| BBP61-0516 | 15.1 | 5.0-7.0 | 8.0 | 1.5 | 2.6 | 5.2 | |||

| 4.8 (3/16") |  | BBP61-0611 | 12.9 | 1.5-3.5 | 9.6 | 1.5 | 3.1 | 5.5 | 5.0 |

| BBP61-0614 | 15.5 | 3.5-6.0 | 9.6 | 1.5 | 3.1 | 5.5 | 5.0 | ||

| BBP61-0618 | 18.5 | 6.0-8.5 | 9.6 | 1.5 | 3.1 | 5.5 | 5.0 |

Aplikasi

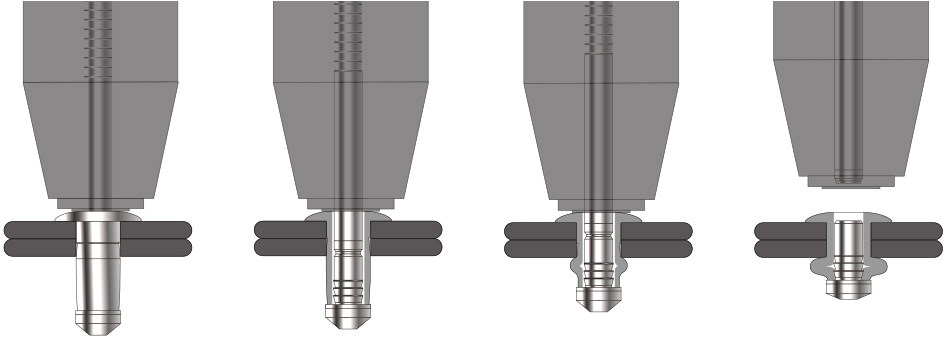

Paku keling buta tipe Uni-Grip adalah paku keling buta tipe struktural.Rivet buta tipe uni grip narik senapan keling dadi jinis drum tunggal nalika riveting rivets, clamp loro bagean struktural kanggo riveted, lan ngurangi tekanan ing lumahing bagean struktural.Iku cocok kanggo riveting intensitas dhuwur.Bagian terstruktur tipis.Nduwe efek protèktif tartamtu ing bagean riveting kanggo ngindhari deformasi bolongan riveting lan ngrusak bagean riveting.

Tujuan utama paku keling buta tipe grip Uni umum yaiku kanggo kendaraan, kapal, bangunan, mesin, listrik, pesawat, kontainer, elevator lan industri liyane.

Apa cara kanggo nyegah karat saka Paku Keling Buta

1. Plating

Plating rivet wuta, cara iki kanggo sijine rivet menyang solusi logam, lan banjur nggunakake saiki kanggo aplikasi lapisan saka logam kanggo lumahing, kang wis akeh efek ing lapisan saka logam.

2. Lapisan mekanik

Plating mechanical saka paku keling wuta kanggo ngidini partikel logam kanggo kadhemen gandheng rivets wuta kanggo mesthekake yen lumahing wuta rivet wis sawetara efek.Ing lapisan mechanical lan electroplating Sejatine padha, nanging cara sing beda.Asil kasebut bisa diarani padha.

3. Perawatan panas

Kanggo perawatan termal saka permukaan paku keling wuta, sawetara permukaan paku keling pop relatif hard, supaya sampeyan bisa panas rivets pop kanggo mesthekake yen keling pop wis cukup atose.Mulane perawatan panas ditindakake.

4. passivation lumahing

Nglewati lumahing keling buta duwe rong fungsi utama.Salah sijine yaiku kanggo nambah kekerasan paku keling, lan liyane yaiku nyuda tingkat oksidasi paku keling buta.