Bahan

| awak | Aluminium(5050 5052 5056) | baja | Baja tahan karat ● | ||||

| Rampung | Dipoles, Dicet | Dilapisi seng | Dipoles | ||||

| Mandrel | alumunium | baja | Baja tahan karat | baja | alumunium | baja | Baja tahan karat ● |

| Rampung | Dipoles | Dilapisi seng | Dipoles | Dilapisi seng | Dipoles | Dilapisi seng | Dipoles |

| Tipe Kepala | Dome, CSK, Flange Gedhe | ||||||

Spesifikasi

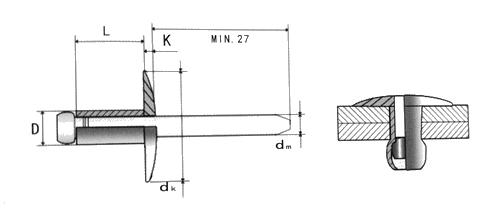

| D NOM. | DRILL NO.&UKURAN LUBANG | GRIP RANGE | L (MAX) | dk NOM. | K MAX | P MIN. | ||

| INCH | MM | INCH | MM | |||||

| 1/8" 3,2 mm | #30 3.3-3.4 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | 0,375" 9.5 | 0,065" 1.65 | 1.06" 27 |

| 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||

| 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||

| 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||

| 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||

| 0.176-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||

| 0,501-0,625 | 12.7-15.9 | 0.775 | 19.7 | |||||

| 5/32" 4,0 mm | #20 4.1-4.2 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0,468" 12.0 | 0,075" 1.90 | 1.06" 27 |

| 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||

| 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||

| 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||

| 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||

| 0,501-0,625 | 12.7-15.9 | 0.800 | 20.3 | |||||

| 3/16" 4,8 mm | #11 4.9-5.0 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0,625" 16.0 | 0,092" 2.33 | 1.06" 27 |

| 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||

| 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||

| 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||

| 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||

| 0,501-0,625 | 12.7-15.9 | 0.825 | 21.0 | |||||

| 0,626-0,750 | 15.9-19.1 | 0.950 | 24.1 | |||||

| 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||

| 0,876-1,000 | 22.5-25.4 | 1.200 | 30.5 | |||||

| 1.001-1.125 | 25.4-28.6 | |||||||

Aplikasi

Paku keling buta tipe flange gedhe, diameter kepala keling iki tambah akeh dibandhingake karo paku keling buta biasa.Nalika riveting karo konektor, rivet wis area kontak luwih gedhe, lumahing support kuwat, lan bisa nambah kekuatan torsi.Keling pop flange gedhe bisa nahan tegangan radial sing luwih dhuwur.

Paku keling pop stainless steel utamané nggunakake kabel utawa piring stainless steel minangka bahan baku, ngiring dening judhul kadhemen utawa stamping lan seri pangolahan.Iki populer banget kanggo nggunakake stainless steel kanggo nggawe paku keling pop, nanging kanggo paku keling pop stainless steel, nduweni papat ciri:

1. tahan suhu dhuwur saka stainless steel paku keling buta.Minangka atose saka stainless steel punika relatif kuwat, rivets sawise produksi wis resistance oksidasi kuwat, lan bisa normal ing suhu dhuwur tanpa kakehan gangguan saka suhu dhuwur.Paku keling pop stainless steel dipasifake sawise manufaktur, sing luwih tahan kanggo suhu dhuwur.

2. Sifat fisik paku keling pop stainless steel duwe tingkat negatif sing relatif dhuwur.Dibandhingake karo rod kawat baja karbon, kita bisa ndeleng manawa tingkat negatif paku keling buta stainless steel kaping lima luwih dhuwur tinimbang baja karbon.Ana koefisien ekspansi ing bagean standar.Liwat tes, kita ngerti yen suhu luwih dhuwur, koefisien ekspansi paku keling pop stainless steel bakal ditingkatake nganti sawetara.

3. Kapasitas beban-bearing paku keling pop stainless steel relatif kuat kanggo paku keling pop stainless steel.Senajan padha ora bisa dibandhingake karo dhuwur-kekuatan bolts, padha uga nyukupi kabutuhan wong normal.

4. Sifat mekanik paku keling pop stainless steel.Ing sifat mekanik, kita bisa ngerti manawa akeh sing ana hubungane karo kabel stainless steel.Handan Wodecy Co., Ltd paku keling buta stainless steel utamané digawe saka 304 utawa 316 kabel utawa piring, lan ora bakal teyeng, duwe resistance karat dhuwur lan resistance nyukur tensile dhuwur.Iki raket banget karo sifat-sifat stainless steel.Kanthi pangembangan rivet pop sing terus-terusan, sifat mekanik kasebut dadi kuwat lan kuwat.