Bahan

| awak | Aluminium(5050 5052 5056 5154) | (AL Mg 1%-1,5%, 2%-2,5%, 3%-3,5%,5%) | ||

| Rampung | Dipoles | RAL Warna Painted | ||

| Mandrel | Aluminium ● | baja | Baja tahan karat | |

| Rampung | Dipoles ● | Dilapisi seng | Dipoles | |

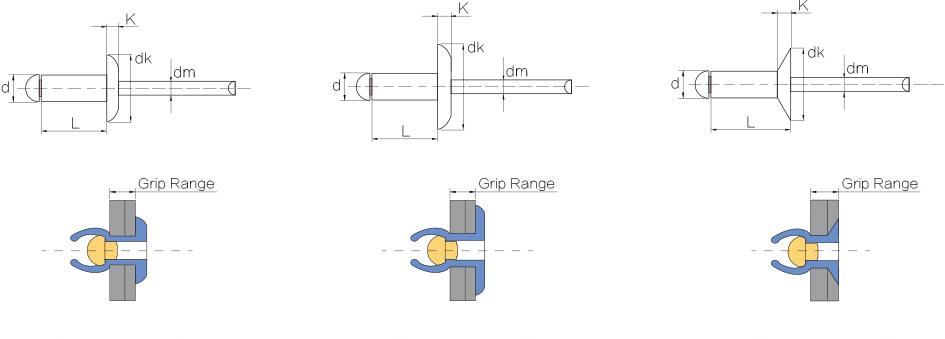

| Tipe Kepala | Dome, CSK, Flange Gedhe | |||

Spesifikasi

| D1 NOM. | DRILL NO. &UKURAN LUBANG | ART.KODE | GRIP RANGE | L (MAX) | D NOM. | K MAX. | P MIN. | nyukur LBS | TENSILE LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 3/32" 2,4 mm | #41 2.5-2.6 | AA32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0,188" 4.8 | 0,032" 0.81 | 1.00" 25.4 | 70 310N | 80 360 N |

| AA34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| AA36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3,2 mm | #30 3.3-3.4 | AA41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0,250" 6.4 | 0,040" 1.02 | 1.06" 27 | 120 530 N | 150 670 N |

| AA42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| AA43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| AA44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| AA45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| AA46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| AA48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| AA410 | 0,501-0,625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4,0 mm | #20 4.1-4.2 | AA52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0,312" 7.9 | 0,050" 1.27 | 1.06" 27 | 190 850 N | 230 1020 N |

| AA53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| AA54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| AA56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| AA58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| AA510 | 0,501-0,625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| AA516 | 0,876-1,000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4,8 mm | #11 4.9-5.0 | AA62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0,375" 9.5 | 0,060" 1.52 | 1.06" 27 | 260 1160 N | 320 1430 N |

| AA63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| AA64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| AA66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| AA68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| AA610 | 0,501-0,625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| AA612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| AA614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| AA616 | 0,875-1,000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| AA618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| AA620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6,4 mm | F 6.5-6.6 | AA82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0,080" 2.03 | 1.25" 32 | 460 2050 N | 560 2500N |

| AA84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| AA86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| AA88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| AA810 | 0,501-0,625 | 12.7-15.9 | 0,875 | 22.2 | |||||||

| AA812 | 0,626-0,750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| AA814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| AA816 | 0,876-1,000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| AA818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Aplikasi

Keling open end aluminium lengkap kami nggunakake kabel paduan aluminium berkualitas tinggi.Sawise riveting, Iku ora bakal teyeng.Dibandhingake karo paku keling biasa, intensitas paku keling kurang, saengga cocok kanggo nyambungake bahan alus.Keling pop aluminium bisa dipérang dadi keling kepala kubah, paku keling countersunk lan keling kepala flange gedhe. Lan bahan paduan aluminium duwe pilihan multi alu mg 2% 2,5% 3,5% lan 5% (5052 5154 5056).

Fixpal open type pop rivets duwe kaluwihan saka operasi gampang, riveting banget, katon ayu, sifat fisik dhuwur.Pilihan sampurna saka siji-sisi riveting.Aluminium pop rivets bisa digunakake digunakake ing macem-macem kendaraan, prau, Manufaktur mesin, electronics, instrumentation, mesin pangan, peralatan medical, construction, dekorasi lan wilayah fastening liyane.

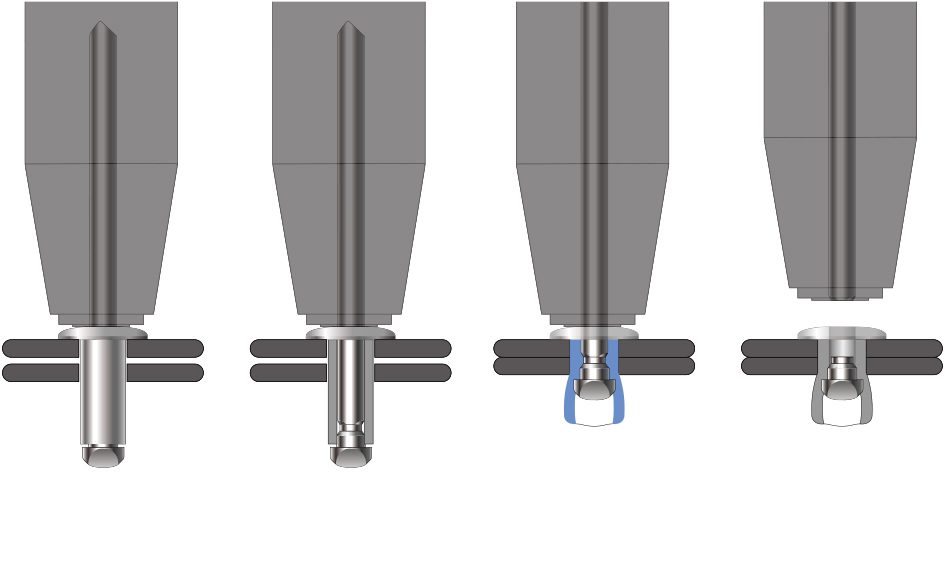

Masalah lan alasan nalika nggunakake paku keling buta:

1. Burrs: Sawise riveting, mandrel bejat karo burrs liwat bolongan rivet;utawa bolongan riveting protrudes saka njaba kanggo mbentuk burr spatula.

Penyebab burrs: diameteripun mandrel cilik;bahan keling alus;diameteripun bolongan pengeboran saka workpiece gedhe banget;spesifikasi moncong bedhil rivet gedhe banget;

2. Kepala paku tiba: Sawise keling ditarik, sirah keling inti ora bisa dibungkus lan tiba saka keling.

Alasan kanggo tiba ing sirah rivet inti yaiku: diameter tutup kuku gedhe banget;keling luwih cendhek, lan kekandelan rivet ora cocog.

3. rivet cracking: Sawise riveting, keling wis pulsed utawa pecah rampung.

Alasan kanggo retak rivet yaiku: kekerasan sing berlebihan sawise annealing riveting utawa perawatan sing ora digawe panas, topi inti kuku gedhe banget.