Bahan

| awak | baja |

| Rampung | Dilapisi seng |

| Mandrel | baja |

| Rampung | Dilapisi seng |

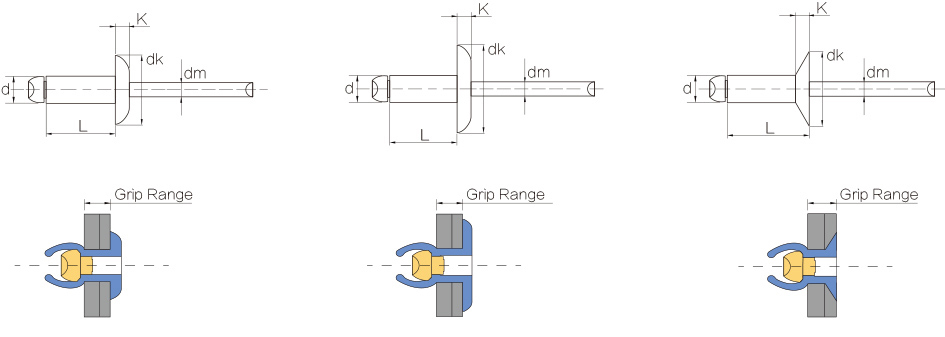

| Tipe Kepala | Dome, CSK, Flange Gedhe |

Spesifikasi

| D1 NOM. | DRILL NO. &UKURAN LUBANG | ART.KODE | GRIP RANGE | L (MAX) | D NOM. | K MAX. | P MIN. | nyukur LBS | TENSILE LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 3/32" 2,4 mm | #41 2.5-2.6 | SS32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0,188" 4.8 | 0,032" 0.81 | 1.00" 25.4 | 130 580N | 170 760N |

| SS34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| SS36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3,2 mm | #30 3.3-3.4 | SS41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0,250" 6.4 | 0,040" 1.02 | 1.06" 27 | 260 1160N | 310 1380N |

| SS42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| SS43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| SS44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| SS45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| SS46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| SS48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| SS410 | 0,501-0,625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4,0 mm | #20 4.1-4.2 | SS52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0,312" 7.9 | 0,050" 1.27 | 1.06" 27 | 370 1650N | 470 2100N |

| SS53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| SS54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| SS56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| SS58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| SS510 | 0,501-0,625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| SS516 | 0,876-1,000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4,8 mm | #11 4.9-5.0 | SS62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0,375" 9.5 | 0,060" 1.52 | 1.06" 27 | 540 2400N | 680 3030N |

| SS63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| SS64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| SS66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| SS68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| SS610 | 0,501-0,625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| SS612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| SS614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| SS616 | 0,876-1,000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| SS618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| SS620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6,4 mm | F 6.5-6.6 | SS82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0,080" 2.03 | 1.25" 32 | 1000 4450N | 1240 5520N |

| SS84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| SS86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| SS88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| SS810 | 0,501-0,625 | 12.7-15.9 | 0,875 | 22.2 | |||||||

| SS812 | 0,626-0,750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| SS814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| SS816 | 0,876-1,000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| SS818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Aplikasi

baja rivet wuta mbukak mburi ora mung ease kanggo nggunakake, efficiency dhuwur, kurang gangguan, bisa nyuda kakiyatan pegawe lan karakteristik liyane, nanging uga sambungan tightness.Paku keling baja bisa dipérang dadi paku keling kepala kubah, paku keling countersunk lan paku keling kepala flange gedhe.Kekuwatan tarik lan geser saka paku keling buta baja luwih dhuwur tinimbang paku keling aluminium standar.Kang digunakake digunakake ing industri, bisa nyukupi kabutuhan panjalukan kekuatan dhuwur.

Masalah lan alasan nalika nggunakake pop rivet:

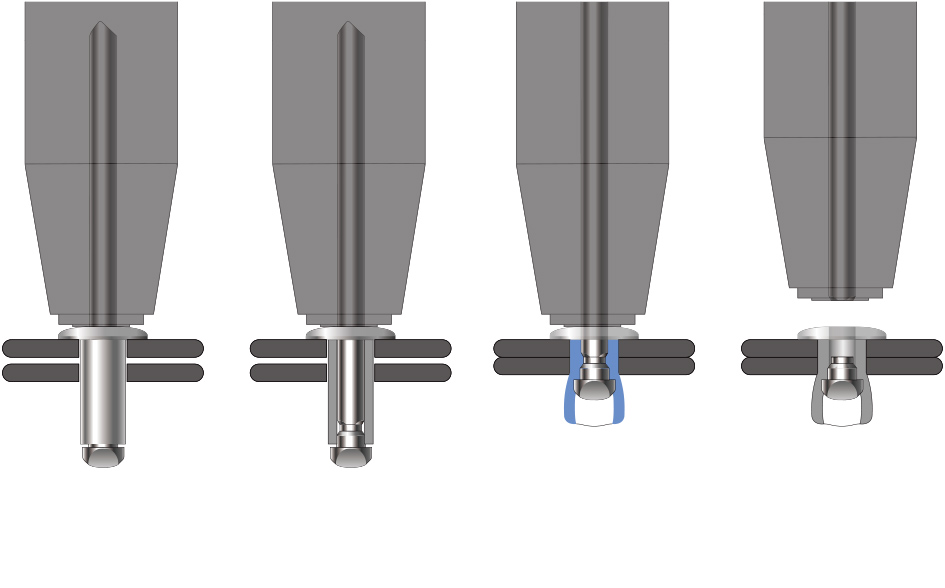

4.Keling pop ditarik liwat: mandrel rivet wis kebak ditarik metu saka rivet, lan mandrel wis bejat.Sawise riveting, ninggalake bolongan kosong ing rivet.

Alasan kanggo narik liwat: kakehan rivet mandrel tension;diameteripun cilik saka tutup mandrel;bahan riveting alus;lumahing bolongan utama banget lubricated.

5.Jump sirah utawa drum ora cukup: Nalika narik rivets, inti rivet njedhul munggah rampung, utawa rivet ora swell.

Alasan kanggo kedadean iki yaiku: kontrol gaya tensile kurang banget nalika inti kuku digawe;awak riveting dhuwur (anil ora rata);

6. Ngaso sawise riveting: Sawise riveting, awak riveting ngeculke ing bolongan workpiece.