Bahan

| awak | Aluminium ( 5056) ● | baja | Baja tahan karat | ||||

| Rampung | Dipoles | Dilapisi seng | Dipoles | ||||

| Mandrel | alumunium | Baja ● | Baja tahan karat | baja | alumunium | baja | Baja tahan karat |

| Rampung | Dipoles | Dilapisi seng | Dipoles | Dilapisi seng | Dipoles | Dilapisi seng | Dipoles |

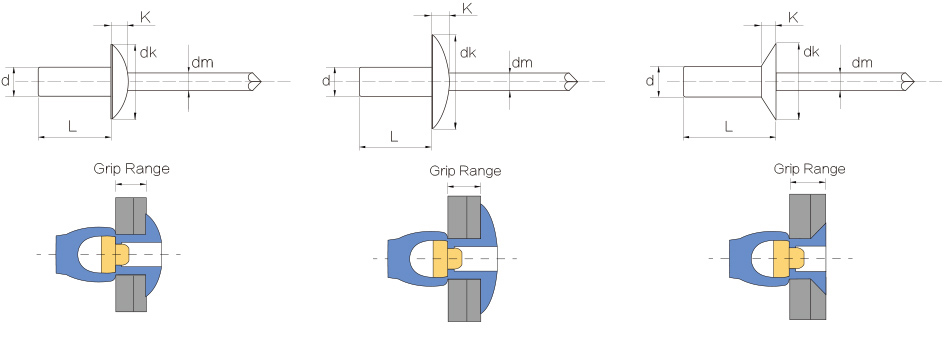

| Tipe Kepala | Dome, CSK, Flange Gedhe | ||||||

Spesifikasi

| D1 NOM. | DRILL NO. $UKURAN HOLE | ART.KODE | GRIP RANGE | L (MAX) | D NOM. | K MAX. | P MIN. | nyukur LBS | TENSILE LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 1/8" 3,2 mm | #30 3.3-3.4 | ASF41 | 0.020-0.062 | 0.5-1.6 | 0.297 | 7.5 | 0,238" 6.0 | 0,050" 1.27 | 1.06" 27 | 240 1070N | 280 1250N |

| ASF42 | 0.063-0.125 | 1.6-3.2 | 0.360 | 9.1 | |||||||

| ASF43 | 0.126-0.187 | 3.2-4.8 | 0.422 | 10.7 | |||||||

| ASF44 | 0.188-0.250 | 4.8-6.4 | 0.485 | 12.3 | |||||||

| ASF45 | 0.251-0.312 | 6.4-7.9 | 0.547 | 13.9 | |||||||

| ASF46 | 0.313-0.375 | 7.9-9.5 | 0.610 | 15.5 | |||||||

| ASF48 | 0.376-0.500 | 9.5-12.7 | 0.735 | 18.7 | |||||||

| 5/32" 4,0 mm | #20 4.1-4.2 | ASF52 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0,312" 7.9 | 0,065" 1.65 | 1.06" 27 | 350 1560N | 480 2140N |

| ASF53 | 0.126-0.187 | 3.2-4.8 | 0.437 | 11.1 | |||||||

| ASF54 | 0.188-0.250 | 4.8-6.4 | 0.500 | 12.7 | |||||||

| ASF55 | 0.251-0.312 | 6.4-7.9 | 0.562 | 14.3 | |||||||

| ASF56 | 0.313-0.375 | 7.9-9.5 | 0.625 | 15.9 | |||||||

| ASF58 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| 3/16" 4,8 mm | #11 4.9-5.0 | ASF62 | 0.020-0.125 | 0.5-3.2 | 0.406 | 10.3 | 0,375" 9.5 | 0,080" 2.03 | 1.06" 27 | 500 2230N | 690 3070N |

| ASF63 | 0.126-0.187 | 3.2-4.8 | 0.468 | 11.9 | |||||||

| ASF64 | 0.188-0.250 | 4.8-6.4 | 0.531 | 13.5 | |||||||

| ASF66 | 0.251-0.375 | 6.4-9.5 | 0.656 | 16.7 | |||||||

| ASF68 | 0.376-0.500 | 9.5-12.7 | 0.781 | 19.8 | |||||||

| ASF610 | 0,501-0,625 | 12.7-15.9 | 0.906 | 23.0 | |||||||

| ASF612 | 0,626-0,750 | 15.9-19.1 | 1.026 | 26.1 | |||||||

| 1/4" 6,4 mm | F 6.5-6.6 | ASF82 | 0.020-0.125 | 0.5-3.2 | 0.445 | 11.3 | 0.500" 12.7 | 0.100" 2.54 | 1.25" 32 | 900 4000N | 1100 4890N |

| ASF84 | 0.126-0.250 | 3.2-6.4 | 0.570 | 14.5 | |||||||

| ASF86 | 0.251-0.375 | 6.4-9.5 | 0.695 | 17.7 | |||||||

| ASF88 | 0.376-0.500 | 9.5-12.7 | 0.820 | 20.8 | |||||||

| ASF810 | 0,501-0,625 | 12.7-15.9 | 0.945 | 24.0 | |||||||

| ASF812 | 0,626-0,750 | 15.9-19.1 | 1.070 | 27.2 | |||||||

| ASF814 | 0.751-0.875 | 19.1-22.2 | 1.195 | 30.4 | |||||||

| ASF816 | 0,876-1,000 | 22.2-25.4 | 1.320 | 33.5 | |||||||

Aplikasi

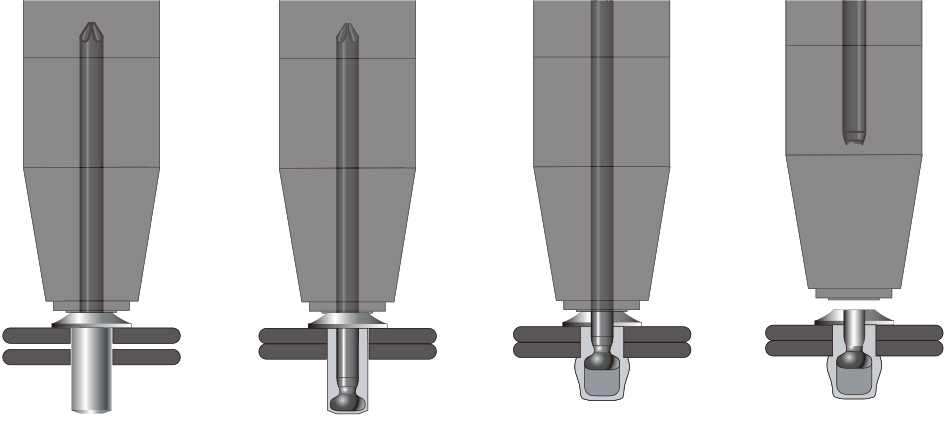

Keling pop minangka jinis paku keling sing digunakake kanggo rivet siji-sisi, nanging kudu dikeling nganggo alat khusus - pistol keling (manual, listrik).Iki jenis paku keling utamané cocok kanggo kesempatan riveting ngendi iku ora trep kanggo nggunakake rivets biasa (sing kudu riveted saka loro-lorone), supaya iku digunakake digunakake ing bangunan, mobil, kapal, pesawat, mesin, electrical Perkakas, Furnitur lan. produk liyane.Antarane wong-wong mau, rivets pop kepala bunder jinis mbukak sing paling akeh digunakake, paku keling pop countersunk cocok kanggo acara riveting ing ngendi kinerja Gamelan dibutuhake, lan paku keling pop jinis tertutup cocok kanggo acara riveting ing ngendi beban dhuwur lan tartamtu. kinerja sealing dibutuhake.

Paku Keling Tipe Disegel dirancang khusus kanggo mbungkus sirah kuku sawise riveting, supaya ora teyeng.Rivet wuta tutup ditutup cocok banget kanggo macem-macem aplikasi kanthi syarat anti banyu.Keling jinis iki nduweni gaya geser sing dhuwur, tahan geter lan tahan tekanan dhuwur.

Tips untuk paku keling buta Pilih:

Ukuran lubang pengeboran paku keling min + 0,1 max + 0,2.

Kekandelan total benda kerja umume 45% - 65% saka dawa keling Luwih becik ora ngluwihi 60%.Kajaba iku, dawa kerja sing cendhak banget uga nyusahake.Disaranake 50% - 60% umume Yen dawa rivet dawa banget, sirah pier rivet gedhe banget, lan rod rivet gampang ditekuk;Yen dawa rivet cendhak banget, kekandelan pier ora cukup, lan cetakan sirah rivet ora lengkap, nyebabake kekuwatan lan kenceng.Ora apik yen dawa keling dawa banget utawa cendhak banget.Mung dawa sing tepat bisa entuk efek riveting paling apik.Contone, yen total kekandelan loro utawa luwih workpieces 6mm, dawa keling kudu 9,23 - 13,3 mm.Ing kasus iki, luwih becik nggunakake paku keling dawane 12mm.